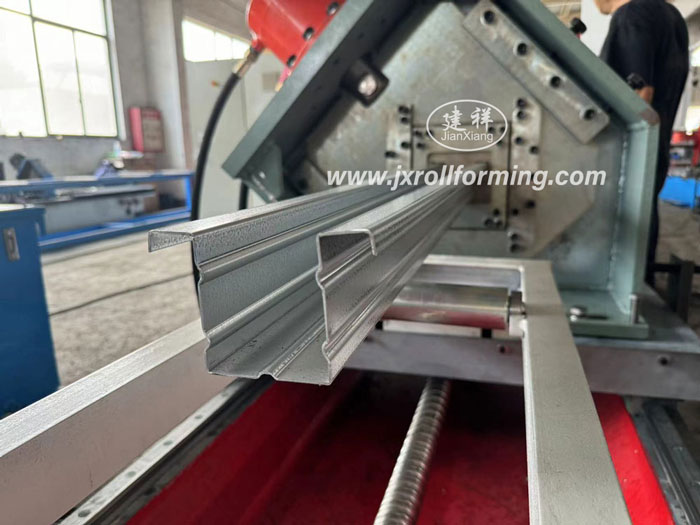

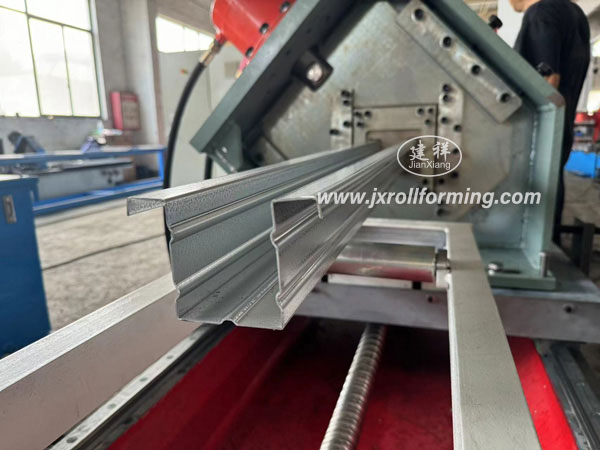

Solar Top Hat Channel Roll Forming Machine

Description

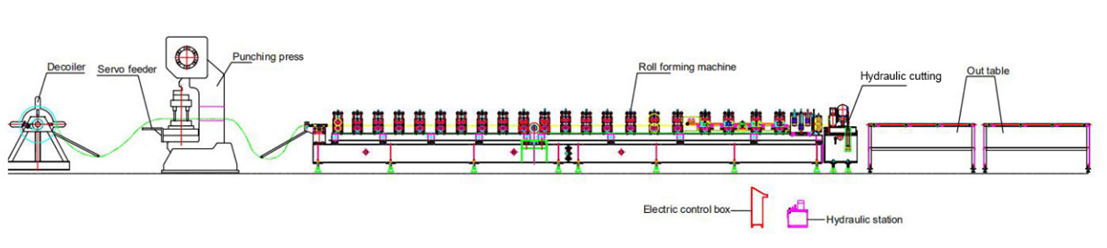

Solar Top Hat Channel Roll Forming Machine is a specialized design equipment used to manufacture solar top hat channels designed for solar strut channel installation. The whole solar top hat channel roll forming machine is composed of decoiler, leveler, servo feeder, punch press, main forming machine, hydraulic system, PLC control system, etc. These machines automatically shape coils of steel into specific profiles that are then used as part of the seismic support systems in construction.

Main Components of Solar Top Hat Channel Roll Forming Machine

1. Decoilier: this component holds and steadily releases the coil of metal sheet to be fed into the main forming machine.

2. Main roll forming machine: this is the core part of the machine, consisting of a series of stations with rollers that progressively shape the metal strip into the desired profile. Each station makes incremental bends and curves until the final shape is achieved.

3. Cut- Off Unit: Once the metal strip is formed into the unistrut seismic bracing channel, it needs to be cut into specific lengths. This is done by the hydraulic cutting device.

4. Output Table: after Unistrut seismic bracing channels are formed and cut, they are typically conveyed to an output table for collection and further handling.

Advantages of Solar Top Hat Channel Roll Forming Machine

1. Efficiency and Consistency: solar top hat roll forming machine can produce long lengths of solar top hat channels quickly and with precise conformity to specifications.

2. Cost-effectiveness: Since roll forming is a continuous process with minimal material waste, it is highly cost-effective, particularly for large-scale production.

3. Customization: The machine settings can be adjusted to produce various.

Application

Solar top hat channels are structural components designed to provide structural support and stability to solar mounting application. The installation of solar top hat channel typically involves the use of robust metal framing components that are engineered to comply with local building codes. These components includes struts, fittings, and accessories that are interconnected to create a flexible yet strong bracing system capable of withstanding lateral forces generated during an earthquake.

Working Process

Operation Flow:

5T Decoiler- Roll forming machine-Hydraulic servo follow cut-Out table

We are professional manufacturer of roll forming machines focused on Unistrut seismic bracing channel industry for more than 30 years, in China, about 90% of the Unistrut seismic bracing channel manufacturers use our machines. The advantage of using our Unistrut seismic bracing channel roll forming machine include high efficiency ( that you just need set the product length and quantity on touch screen, then the machine will run automatically), consistent product quality, and the ability to produce long lengths of channel without joints.

Technical Specification

|

Solar Top Hat Channel Roll Forming Machine |

||

|

No. |

Item |

Specification |

|

1 |

Suitable material |

Galvanized Coil, PPGI, Carbon steel Coil |

|

Thickness(mm):1.5-3.0 |

||

|

Yield strength: 250 - 550MPa |

||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

||

|

2 |

Nominal forming speed(m/min) |

0-30 |

|

3 |

Forming station |

18 stations |

|

4 |

Main motor power |

22Kw |

|

5 |

Roller material |

Cr12Mov |

|

6 |

Decoiler |

Manual decoiler |

|

7 |

PLC brand |

Delta, Taiwan |

|

8 |

Inverter brand |

Yaskawa |

|

9 |

Driving system |

Gearbox drive |

|

10 |

Rollers’ material |

Cr12Mov( best roller material) |

|

11 |

Station structure |

Casting frame structure |

|

12 |

Punching system |

Punch by press machine |

|

13 |

Power supply |

380V 50Hz 3PH |

|

14 |

Machine color |

Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing Solar Top Hat Channel Roll Forming Machine?

A: We have rich experience of producing Solar Top Hat Channel Roll Forming Machine, till now more than 300 sets solar strut channel roll forming machine produced and sold to customers local China and all over the world.

2. Q: What is delivery time of Unistrut Seismic Bracing Roll Forming Machine?

A: 60 days after contract confirmation.

3. Q: What is your machine speed?

A: Production speed is depending on customer’s punch hole requirement, usually forming speed is 0-30m/min.

4. Q: What is machine total land area?

A: Total factory area required about 25000mm(Length) x 30000mm (Width)

5. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Machine Photo