Solar C Channel Roll Forming Machine

Solar C Channel Roll Forming Machine

Description

Solar C Channel Roll Forming Machine is designed to produce Steel C channel solar panel bracket which is applicable to flat concrete roof and large solar plant in open field ground. This solar C channel roll forming machine is composed of 5 Ton decoiler, main roll forming machine, hydraulic punch device, servo follow cutting device, outer table, hydraulic system, and electrical control system. Controlled by PLC control system, this solar C channel roll forming machine is fully automatically operation control. It can produce C strut channel with width 60-120mm, height 40-60mm, thickness range from 1.5-2.5mm. The line production speed can be maximum 20m/min. About 90% of China solar bracket cold rolled C steel strut channel purlins are made by our strut C channel roll forming machines. In the galvanized strut steel solar channel center of Tianjin city, more than 500 solar strut channel manufacturers use our machines.

Application

Steel C channel solar panel brackets are commonly used in solar panel installations to provide structural support and mounting for the panels. Here are some typical applications, such as roof mounting, ground mounting, etc, which offer a robust and flexible mounting solution for various solar panel installation scenarios, contributing to the widespread adoption of solar energy systems.

Working Process

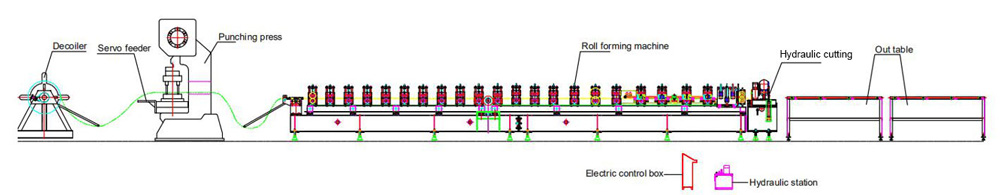

Operation Flow:

5T Decoiler- Servo Feeder- Punching press-Roll forming machine-Hydraulic servo follow cut-Out table

We are professional manufacturer focused on solar strut channel industry for more than 30 years, in China, about 90% of the solar strut channel manufacturers use our machines.

Technical Specification

|

Solar C Channel Roll Forming Machine |

||

|

No. |

Item |

Specification |

|

1 |

Suitable material |

Galvanized Coil, PPGI, Carbon steel Coil |

|

Thickness(mm):1.5-2.5 |

||

|

Yield strength: 250 - 550MPa |

||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

||

|

2 |

Nominal forming speed(m/min) |

0-30 |

|

3 |

Forming station |

15 statons |

|

4 |

Decoiler |

Manual decoiler |

|

5 |

PLC brand |

Delta, Taiwan |

|

6 |

Inverter brand |

Yaskawa |

|

7 |

Driving system |

Gearbox drive |

|

8 |

Rollers’ material |

Cr12Mov( best roller material) |

|

9 |

Station structure |

Casting frame structure |

|

10 |

Punching system |

Punch by press machine |

|

11 |

Power supply |

380V 50Hz 3PH |

|

12 |

Machine color |

Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing Solar C Channel Roll Forming Machine?A: We have rich experience of producing solar C channel roll forming machine, till now more than 900 sets C channel roll forming machine produced by us.

2. Q: How many sizes can be made in one machine?

A: One machine could produce Solar C channel size of width 60-120mm, height 40-60mm, any size can be produced, and punch holes can be produced also as per customer’s drawing requirement.

3. Q: What is delivery time of solar C channel roll forming machine?

A: 60 days after contract confirmation.

4. Q: What is your machine speed?

A: Production speed is depending on customer’s punch hole requirement, usually forming speed is 0-30m/min.

5. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

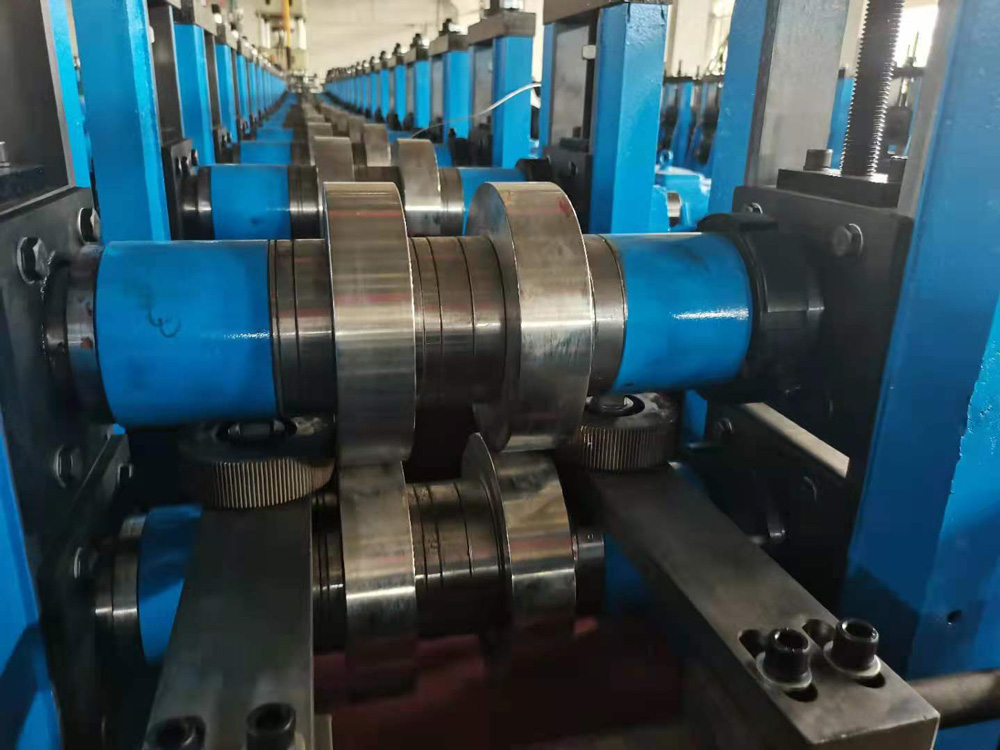

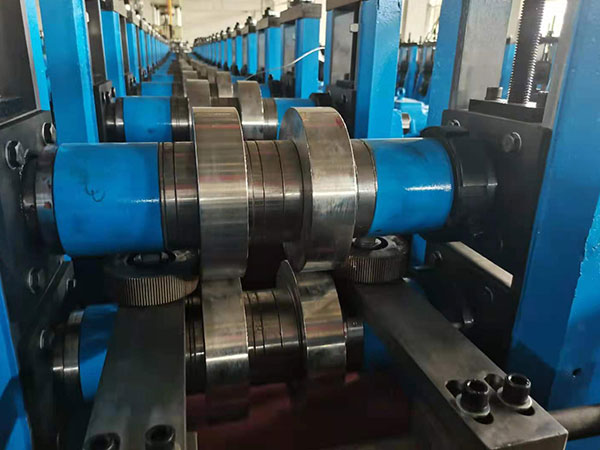

Machine Photo