solar strut channel roll forming machine

Description

The solar strut channel roll forming machine (also called Unistrut machine or solar photovoltaic channel roll forming machine is a specialized design equipment used to manufacture metal channels, often referred to as solar strut channels (both solid strut channel and slotted strut channel available)or support channels. These unistrut channels are extensively used in the construction of solar panel frames and mounting systems. The whole solar strut channel roll forming machine is composed of decoiler, leveler, servo feeder, press machine, main roll forming machine, hydraulic cutting machine, outer table, hydraulic system and PLC control system.

Application

Solar strut channels are structural components commonly used in the construction and installation of solar panel systems. These channels serve multiple functions and are integral to both residential and commercial solar installations. Here’s a closer look at their applications:- Mounting Framework: Solar strut channels provide a robust framework to which solar panels can be securely attached. They are used to create the mounting racks that support solar panels either on rooftops or on the ground. The channels allow for flexible placement of panels, optimizing orientation and tile for maximum solar exposure.

- Adjustability and Configuration: Due to the slotted design of most solar strut channels, they offer great flexibility in terms of configuration. This design allows components to be easily moved along the channel to adjust the spacing and positioning of solar panels as required by specific site conditions or to enhance energy efficiency.

- Durability and Support: Made typically from steel or aluminum, these channels are durable and capable of withstanding various environmental conditions including wind, rain, and heavy snow loads. This makes them ideal for long- term outdoor use in supporting solar panels.

- Cabe Management: Solar strut channel can also be used for managing or organizing cables and wires associated with solar panels. This helps in maintaining an orderly system, protecting cables from mechanical damage, and reducing maintenance issues.

Working Process

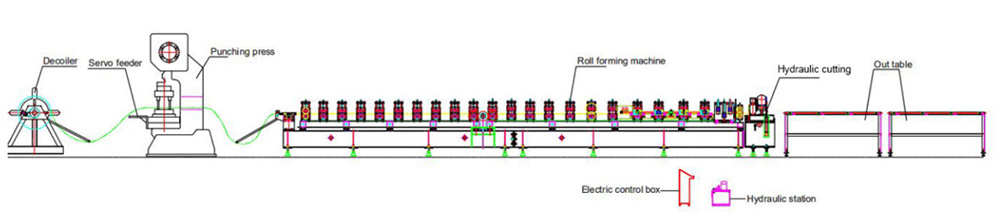

Operation Flow:

5T Decoiler- Servo Feeder- Punching press-Roll forming machine-Hydraulic servo follow cut-Out table

We are professional manufacturer of roll forming machines focused on solar strut channel industry for more than 30 years, in China, about 90% of the solar strut channel manufacturers use our machines. The advantage of using our solar strut channel roll forming machine include high efficiency ( that you just need set the product length and quantity on touch screen, then the machine will run automatically), consistent product quality, and the ability to produce long lengths of channel without joints. These characteristics are essential for the structural integrity and durability of solar panel mounting systems.

Technical Specification

|

Solar C Channel Roll Forming Machine |

||

|

No. |

Item |

Specification |

|

1 |

Suitable material |

Galvanized Coil, PPGI, Carbon steel Coil |

|

Thickness(mm):1.5-2.5 |

||

|

Yield strength: 250 - 550MPa |

||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

||

|

2 |

Nominal forming speed(m/min) |

0-30 |

|

3 |

Forming station |

22 tatons |

|

4 |

Decoiler |

Manual decoiler |

|

5 |

PLC brand |

Delta, Taiwan |

|

6 |

Inverter brand |

Yaskawa |

|

7 |

Driving system |

Gearbox drive |

|

8 |

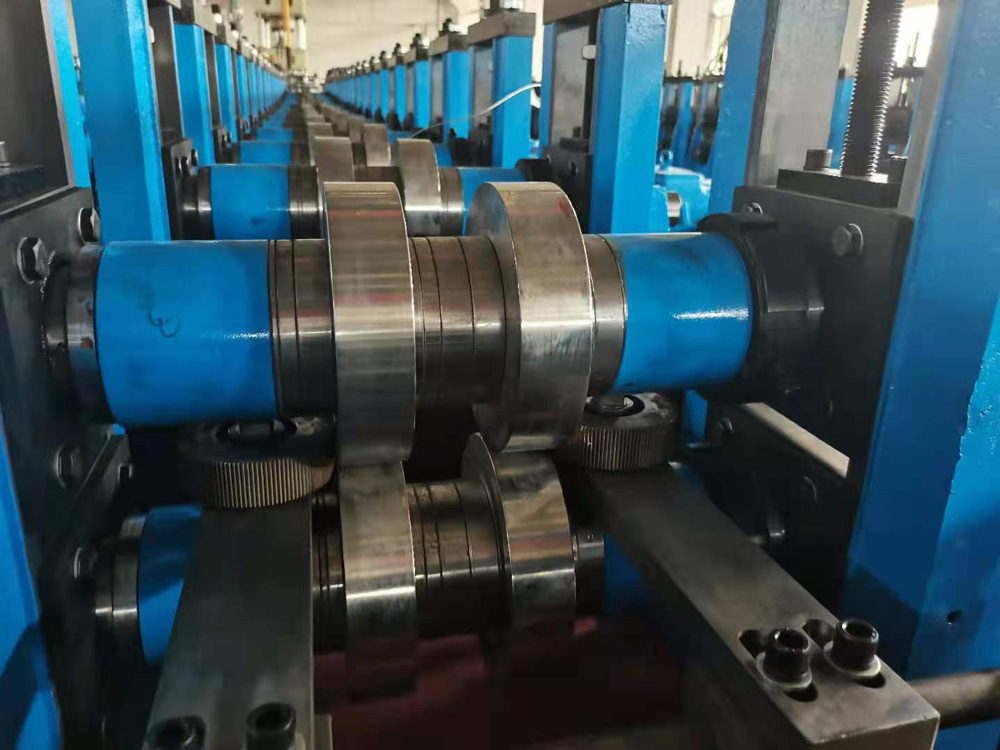

Rollers’ material |

Cr12Mov( best roller material) |

|

9 |

Station structure |

Casting frame structure |

|

10 |

Punching system |

Punch by press machine |

|

11 |

Power supply |

380V 50Hz 3PH |

|

12 |

Machine color |

Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing Solar Strut Channel Roll Forming Machine?

A: We have rich experience of producing solar strut channel roll forming machine, till now more than 1000 sets solar strut channel roll forming machine produced and sold to customers local China and all over the world.

2. Q: How many sizes can be made in one machine?

A: One machine could produce solar strut channel size of 41x21/41x41/41x52/41x62/41x72/41x82mm, thickness 1.5-2.5mm, any size can be produced, and punch holes can be produced also as per customer’s drawing requirement.

3. Q: What is delivery time of solar strut channel roll forming machine?

A: 60 days after contract confirmation.

4. Q: What is your machine speed?

A: Production speed is depending on customer’s punch hole requirement, usually forming speed is 0-30m/min.

5.Q: How does this solar strut channel roll forming machine works?

A: The machine starts with a coil of flat metal sheet , usually made of galvanized coil, zinc aluminum coil, this coil is loaded into the machine where it is gradually uncoiled and fed into the forming process. The core of the machine features a series of rollers arranged in sequential stages. As the metal sheet passes through these rollers, each set incrementally bends and metal closer to the final shape. After the metal has been formed into the continuous channel shape, a cutting device cuts it into required length accordingly to the specifications need for the solar mounting structures. Some machines may also include additional features like punching or stamping mechanisms that create holes or slots or teeth in the channel. These modifications are crucial for facilitating the assembly of the solar panel frames, allowing for connections, and fastening of the solar panels.

6. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Machine Photo