Steel Formwork Roll Forming Machine

Description

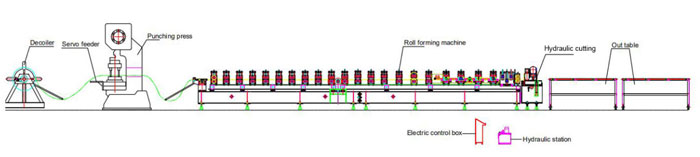

Steel Formwork Roll Forming Machine is a specialized design equipment used to manufacture building steel formwork. Building Steel Formwork is a temporary or permanent mold or structure made from steel, used in construction to shape and support concrete until it hardens and gains sufficient strength. It is a crucial component in modern construction, especially for large-scale projects like high-rise buildings, bridges, and infrastructure. Compared with traditional wood formwork, and aluminum formwork, this roll formed steel formwork save labor cost by 30%, and save material by 50%, and can be repeated use for more than 200 times.The whole steel formwork roll forming machine is composed of decoiler, main forming machine, hydraulic punch device, hydraulic cutting device, PLC control system, etc. Fully automatically controlled by PLC control system, this steel formwork roll forming machine has the advantage of easy operation and fast efficiency.

Application

Steel formwork is widely used in modern construction due to its strength, reusability, cost saving and higher precision.Following are the key applications:

1. High-Rise Buildings & Skyscrapers

- Used for columns, beams, shear walls, and slabs.

- Climbing formwork (slipform/jump form) is ideal for tall structures like cores, elevator shafts, and towers.

- Provides high load-bearing capacity for fast construction.

2. Bridges & Flyovers

- Used for piers, abutments, deck slabs, and girders.

- Modular steel systems allow quick assembly and dismantling.

- Ensures smooth concrete finishes, reducing post-construction work.

3. Tunnels & Underground Structures

- Tunnel formwork is used for metro stations, underground parking, and subways.

- Steel’s rigidity prevents deformation under high concrete pressure.

4. Industrial Structures (Factories, Power Plants, Silos)

- Suitable for heavy-duty foundations, chimneys, and retaining walls.

- Resistant to high temperatures and harsh environments.

5. Residential & Commercial Buildings

- Used for walls, slabs, staircases, and balconies.

- Modular systems speed up construction for mass housing projects.

6. Water & Hydraulic Structures (Dams, Canals, Sewage Tanks)

- Steel formwork provides water-tight joints, preventing leaks.

- Used in curved and complex shapes for spillways and reservoirs.

Working Process

Operation Flow:5T Decoiler- Roll forming machine-Hydraulic servo follow cut-Out table

We are professional manufacturer of roll forming machines focused on building formwork industry for 30 years, in China, about 80% of the steel formwork manufacturers use our machines. The advantage of using our steel formwork forming machines include high efficiency ( that you just need set the product length and quantity on touch screen, then the machine will run automatically), consistent product quality, and the ability to produce long lengths of channel without joints. We also produce solar strut channel roll forming machine, cable tray roll forming machine, highway guardrail roll forming machine, etc.

Technical Specification

|

Steel Formwork Roll Forming Machine |

||

|

No. |

Item |

Specification |

|

1 |

Suitable material |

Galvanized Coil, PPGI, Carbon steel Coil |

|

Thickness(mm):1.5-3.0 |

||

|

Yield strength: 250 - 550MPa |

||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

||

|

2 |

Nominal forming speed(m/min) |

0-30 |

|

3 |

Forming station |

22 stations |

|

4 |

Main motor power |

22Kw |

|

5 |

Roller material |

Cr12Mov |

|

6 |

Decoiler |

Manual decoiler |

|

7 |

PLC brand |

Delta, Taiwan |

|

8 |

Inverter brand |

Yaskawa |

|

9 |

Driving system |

Gearbox drive |

|

10 |

Rollers’ material |

Cr12Mov( best roller material) |

|

11 |

Station structure |

Casting frame structure |

|

12 |

Punching system |

Punch by press machine |

|

13 |

Power supply |

380V 50Hz 3PH |

|

14 |

Machine color |

Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing Steel Formwork Roll Forming Machine?

A: We have rich experience of producing Steel Formwork Roll Forming Machine, till now more than 80 sets steel formwork roll forming machine produced and sold to customers local China and all over the world.

2. Q: What is delivery time of Steel Formwork Roll Forming Machine?

A: 60 days after contract confirmation.

4. Q: What is your machine speed?

A: Production speed is depending on customer’s punch hole requirement, usually forming speed is 0-30m/min.

1. Q: What is machine total land area?

A: Total factory area required about 25000mm(Length) x 30000mm (Width)

5. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Machine Photo